如何使用科学相机进行精密加工

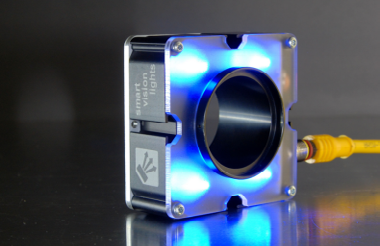

Precision machining is a critical process in various industries, ranging from aerospace to electronics. Achieving high accuracy and quality is always the primary goal. Among the different tools and technologies available, the use of scientific cameras has gained increasing attention. In this article, we will explore the advantages and techniques of using scientific cameras for precision machining, without repeating similar ideas in each paragraph.

The first benefit of using scientific cameras for precision machining is the ability to enhance accuracy. These advanced cameras capture highly detailed images, allowing engineers to closely monitor the machining process. By analyzing these images, potential errors or deviations can be detected and corrected promptly. This level of precision significantly reduces the risk of producing faulty or low-quality machined parts. With scientific cameras, manufacturers can achieve unparalleled precision.

Furthermore, scientific cameras offer unparalleled magnification capabilities. They allow engineers to zoom in and examine even the tiniest details of the machined parts. This level of magnification enables engineers to detect and correct any imperfections, ensuring the final product meets the desired specifications. The high-resolution images obtained from the scientific camera act as a valuable tool for quality control in precision machining.

In addition to accuracy and magnification, scientific cameras enable real-time monitoring of the machining process. By connecting the camera to a computer or monitor, engineers can observe the machining operation without any delay. This real-time monitoring allows for immediate adjustments, preventing any potential issues from escalating. Engineers can intervene promptly if they notice any deviations from the desired outcome, further enhancing the precision and efficiency of the machining process.

Apart from real-time monitoring, scientific cameras also facilitate data analysis. The images captured by the camera can be processed and analyzed using advanced software. This analysis provides valuable insights regarding the machining process, identifying trends and patterns that may affect the final outcome. Engineers can utilize this information to optimize the machining parameters and improve the overall efficiency of the process. The integration of scientific cameras and data analysis has revolutionized precision machining.

To summarize, the use of scientific cameras in precision machining offers various advantages. These cameras enhance accuracy, thanks to the high-resolution images they capture. The magnification capabilities enable engineers to examine even the tiniest details, ensuring the final product meets the desired specifications. Real-time monitoring and instant adjustments minimize potential issues, resulting in an efficient machining process. Finally, the data analysis provided by scientific cameras offers valuable insights for process optimization. Embracing these modern technologies revolutionizes the field of precision machining, setting new standards for accuracy and quality.

In conclusion, the integration of scientific cameras in precision machining has transformed the way manufacturers approach this critical process. By adding unparalleled accuracy, magnification, real-time monitoring, and data analysis capabilities, scientific cameras have become indispensable tools in achieving high precision and quality. As technology continues to advance, scientific cameras are likely to play an even more significant role in precision machining, empowering manufacturers to push the boundaries of what is possible.